|

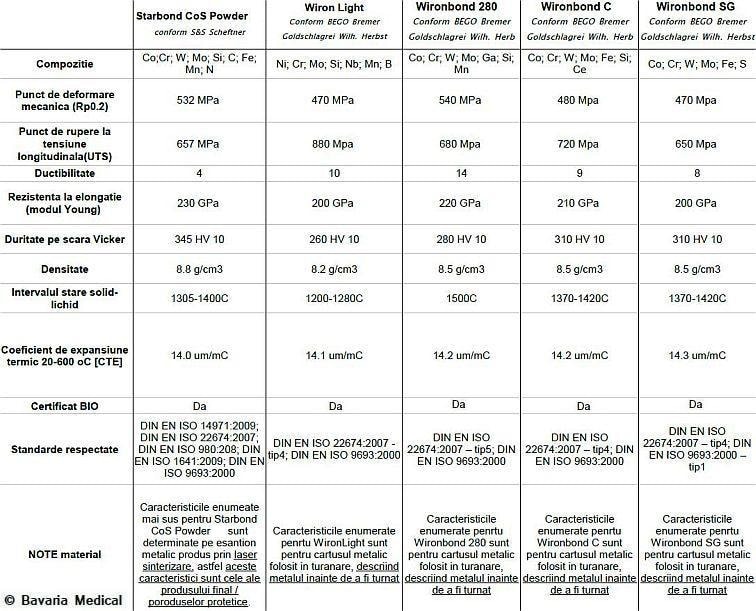

The alloy that we use in the Selective Laser Melting Process is manufactured by S&S Scheftner, the Co-Cr alloy is specially manufactured for dental applications and is in conformity with CE 0197/2008-07. The composition of the Co-Cr alloy that we use is Chrome (59%), Cobalt (25%) and is free of Nickel and Beryllium. |

|

|

By SLM manufacturing process the alloy characteristics are traceable to the final product (composition, mechanical properties, etc)

Starbond CoS Powder alloy is an biocompatible alloy that has in the composition: 59.0% Co; 25.0% Cr; 9.5% W; 3.5% Mo; max 1% Si, max 1.5% C,Fe,Mn,N. The final product obtained using selective laser melting has the fallowing mechanical benefits: - high hardness; - high density; - high yield strength (good for ceramic veneering); - CTE factor (14.0) is perfect for ceramic adhesion in conformity with dental ceramic masses manufacturers; - the Co-Cr structures obtained using selective laser melting have high biocompatibility (better the LWC manufacturing process), the final structure being chemically inert, with high density, without porosity and inclusions, without deformations, perfectly adapted (in full compliance with the CAD model). The Co-Cr alloy is in compliance with the following standards: DIN EN ISO 14971:2009 Medical devices. Application of risk management to medical devices DIN EN ISO 22674:2007 Dentistry - Metallic materials for fixed and removable restorations and appliances DIN EN ISO 980:2008 Symbols for use in the labelling of medical devices DIN EN ISO 1641:2009 Dentistry. Medical devices for dentistry. Materials DIN EN ISO 9693:2000 Metal-ceramic dental restorative systems notes: post-processing CoCr SLM structures CoCr alloy specifications |